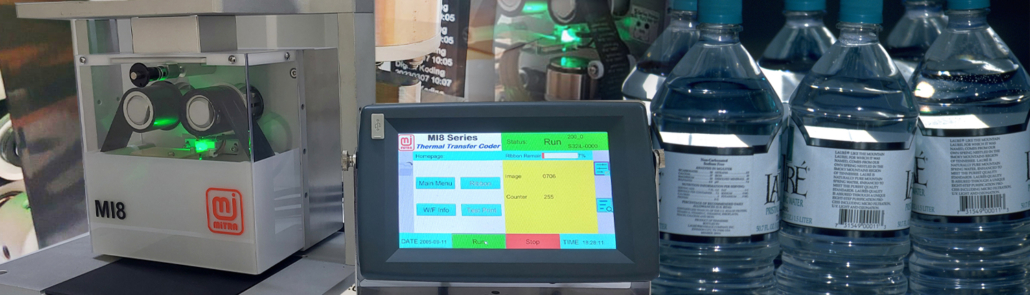

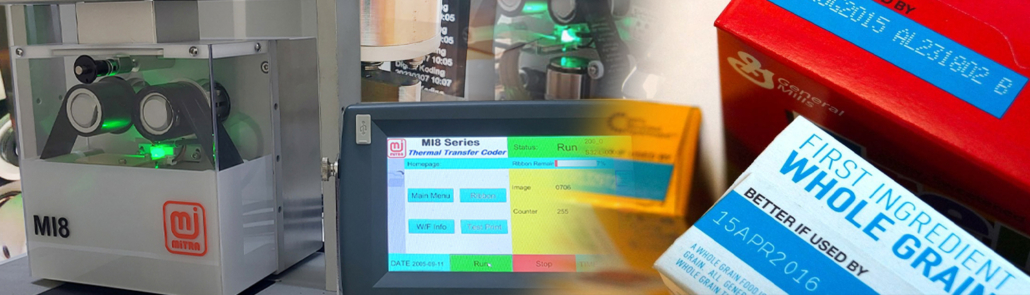

Our thermal transfer printers are developed specifically for flexible materials, offering a better print quality than continuous inkjet and thermal inkjet printing on a wide range of film types.

100% readable codes ensure product traceability with inks specially designed for coding on glass for the food and beverage industries.

We have a variety of coding on glass solutions for each need.

The SmartLase C350laser reduces your operating expenses thanks to ink-free operations. This glass marking machine creates permanent, sharp codes on glass that are ideal for anti-counterfeiting measures, such as a branded vodka that is not on a fast production line.

Alternatively, the ultrafast 9450 S continuous inkjet printeris specially designed for the beverage industry and for priting on glass bottles. It can produce a two-line code on 120,000 containers or packs per hour, and its hygienic stainless-steel design is able to withstand regular washing.

Though it does not directly touch the food, ink applied to the outside of food containers must meet safety requirements, such as being MEK (ketone) free. Returnable glass bottles also require a special alkali-soluble ink that must remain 100% readable until the bottle is returned, but can then be removed and replaced with a new code once it is refilled. For these and other specialized needs, we offer a wide selection of inks, including a unique white ink, to suit glass bottles of different colors.

Ultrafast coding and a choice between permanent or removable codes for plastic bottles.

100% safe and edible inks, compliant with local and national regulations to code on food, eggs and food packaging.

For printing directly on food, we offer a line of continuous inkjet inks together with a line of wax-based, edible hot-melt inks that are FDA, EU, and kosher compliant. For incidental food contact with packaging, a line of inks is also available.

The 9450 continuous inkjet printeroffers traceable egg coding at high-speed. Available in blue or red and compliant with all local and national regulations, these dedicated food-grade inks can be used to code more than 250,000 eggs an hour on an eight-track grading machine.

The 5400 FG printer uses our patented Touch Dry hot-melt edible inks, available in six colors, that will not run or bleed into food. Able to continuously print without line stoppages, this printer can code 4 messages simultaneously on a variety of substrates.

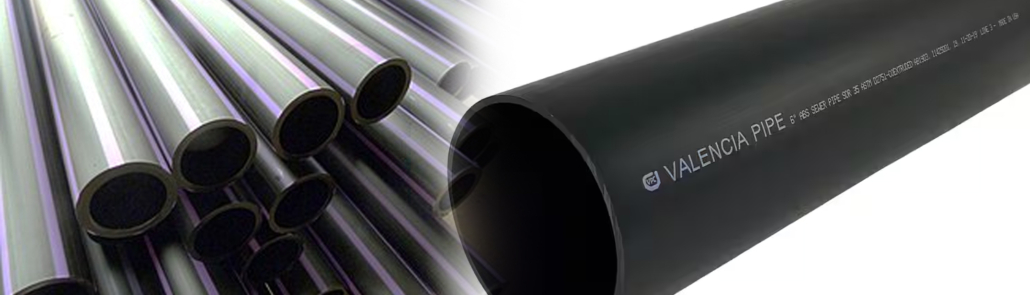

Coding and marking extrusions: high contrast, 100% permanent and readable codes, even on the most difficult plastic substrates

Our 9450 E continuous inkjet extruded material printer, built specifically for the wire and cable industry, delivers cost-effective, high-speed, and high contrast inkjet printing, with no ink migration, on a wide range of substrates and diameters. A variety of specialty inks, including a one-fits-all silver ink and a selection of MEK-free solutions are available for use with this model.

PT Digital Koding Solusindo

Jurumudi Baru, Tangerang, Banten

info@mitracoding.com

+62 896-7646-1899